Dassault Systèmes exposes the diversity of CAD

In addition to the announcements made around its products, Dassault systmes highlighted certain companies. They act in several domains, the virtual reality, the mga-exoskeletons or the fluorescence of phytoplankton. Their common point is to exploit the numerous solutions of the publisher.

Live from Nashville. On the occasion of its 3DExperience World 2023 event, Dassault Systèmes returned at length to the use of these computer-aided design technologies. Several testimonies followed one another on stage in very different sectors from each other.

Bringing phytoplankton to the surface

First company to launch into the Ocean-based Climate Solutions bath, which presents a system capable of reactivating phytoplankton. Composed of unicellular microalgae, it lives on the surface of the oceans to capture the CO2 necessary for its photosynthesis. For experts, phytoplankton constitutes an essential carbon sink for the planet, but it is threatened by climate change (acidity of the oceans, over-enriched nutrients, …).

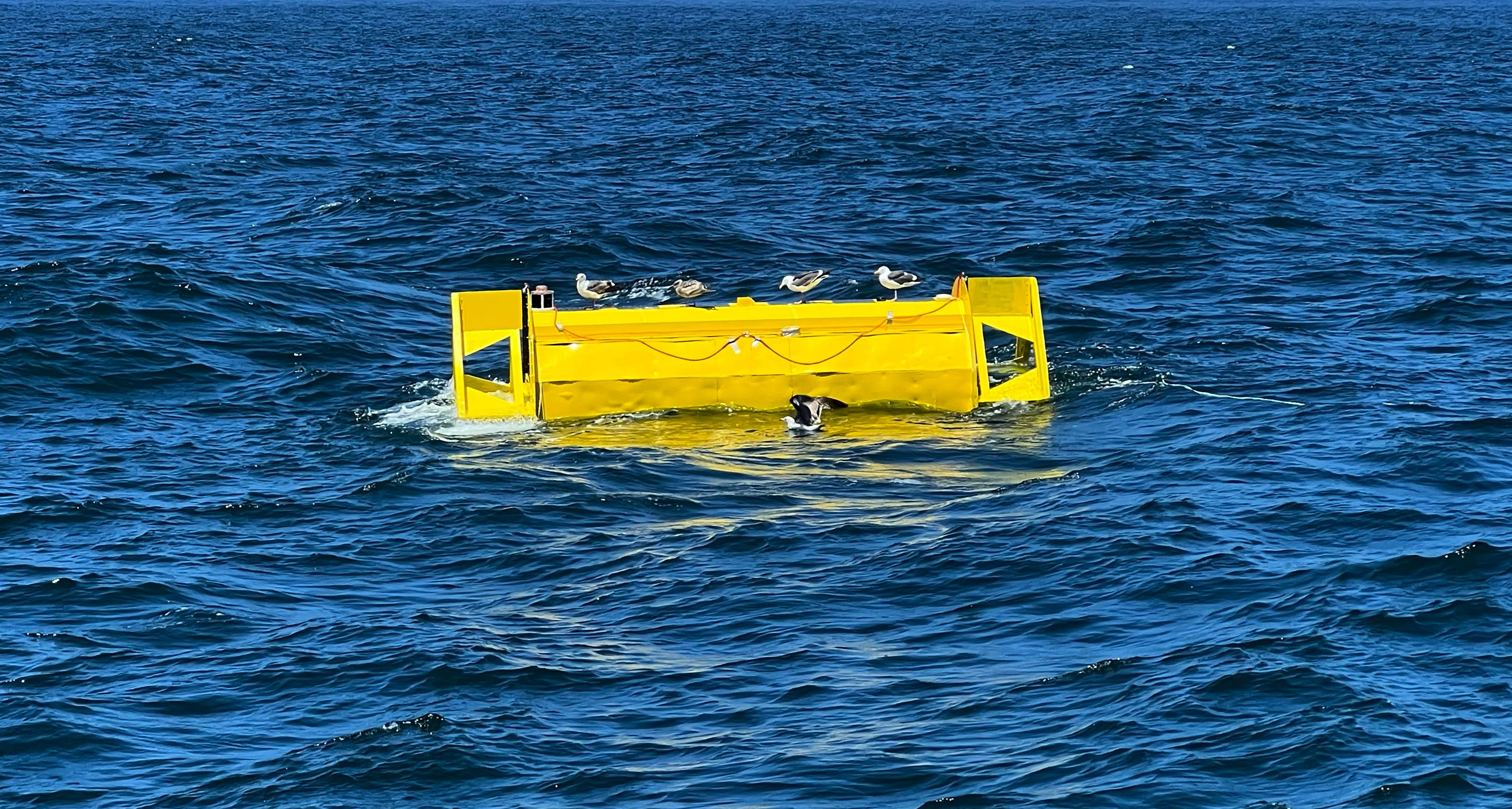

Several pumps have been deployed in particular in Europe and the United States. (Photo Credit: Ocean-based Climate Solutions)

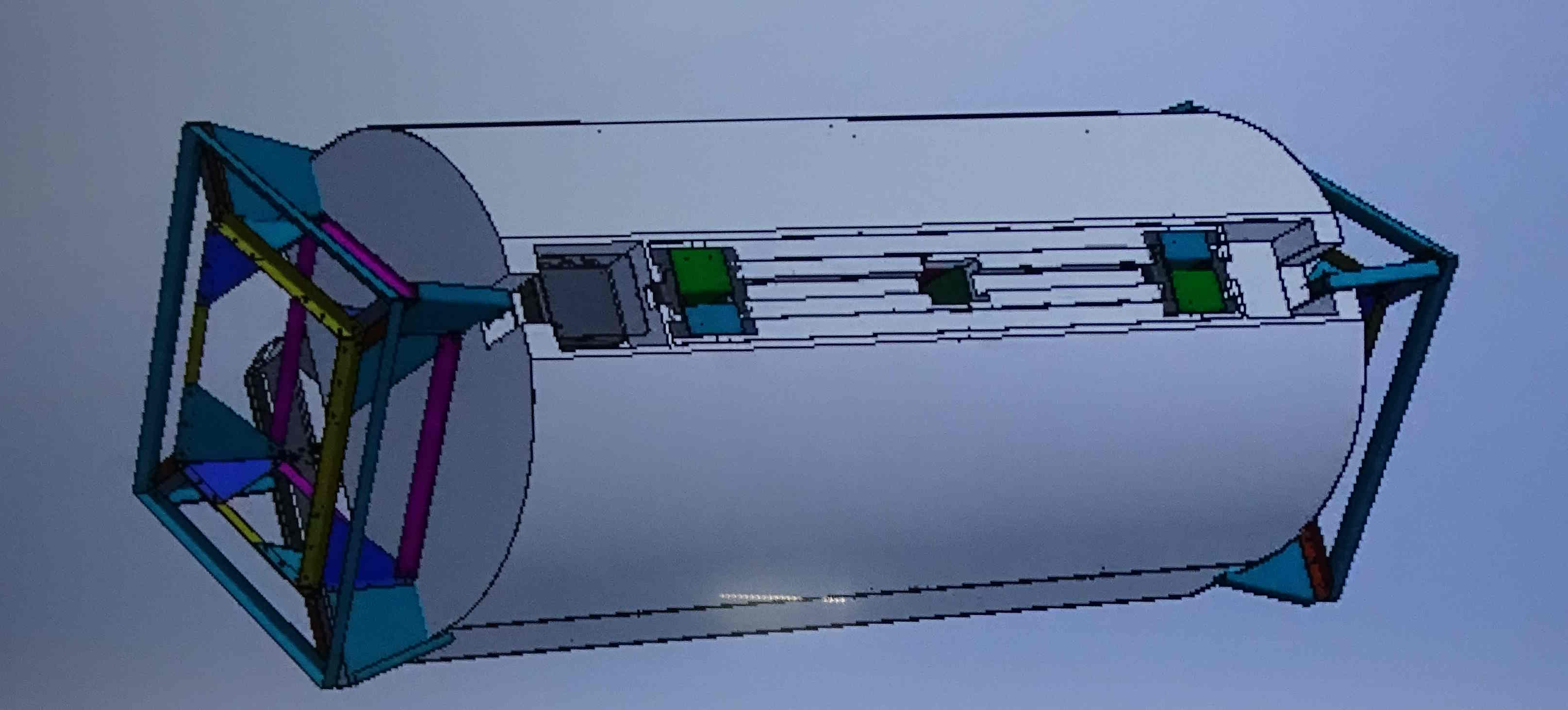

Faced with this risk, the company has imagined a pump capable of raising water from the depths of the ocean (twilight zone at about 200 meters deep) to the surface (sunny zone) to reactivate the development of phytoplankton. Developed by Ocean-based Climate Solutions, this system uses wave and solar energy to operate. Recent deployments have taken place off the Canary Islands and southern California. To create it, she resorted to Solidworks solutions, emphasizes Philip Fullam, chief engineer of the company. Size, absorption capacity, rotation, material, sensors, several parameters have been taken into account to design the pump and simulate its capabilities. “We also needed to exchange a lot with people scattered around the world,” reports the manager, stressing the importance of the 3DExperience platform. “It also makes it possible to ensure the compatibility of projects for those who work on different versions of Solidworks,” he says.

Modeling work of the autonomous pump with the energy of the waves and the sun. (Photo Credit: JC)

Haptic virtual reality blows hot and cold

Another company highlighted, Weart which comes to us from Italy. Its ambition is “to bring touch to virtual reality”, explains Fabio Pizzoti, head of E-novia, the technology consulting agency that accompanied Weart. The haptics market in the AR / VR world is developing more and more with different players, the French Actronika, the Korean Bhaptics and even Meta who is working on a dedicated glove for the metaverse.

The WearT solution includes sensors that are put on the fingers, leaving the movements of the hand free. (Photo Credit: JC)

Where Weart stands out is the ability to “feel” temperature differences. In addition to the virtual reality headset, several sensors are placed on the fingers, which “leaves freedom of movement” assures Fabio Pizotti. Once equipped, the demonstration begins with the passage of the hand near a flame, and the sensations of heat at the tips of the fingers are very present although a little limited (the temperature does not exceed 42 degrees for safety reasons). The feeling is on the other hand much more important on the cold. To develop this hardware and the software, the Weart teams relied on Solidworks solutions, “around simulation for temperature detection, sensor design, virtual reality environment, etc.”. The services were used in an on-premise version, but like Ocean-Based Climate Solutions, Weart uses the 3DExperience platform to collaborate on projects.

In virtual reality, it is possible to approach a source of heat or cold and feel the different temperatures at your fingertips. (Photo Credit: JC)

An extraordinary exoskeleton

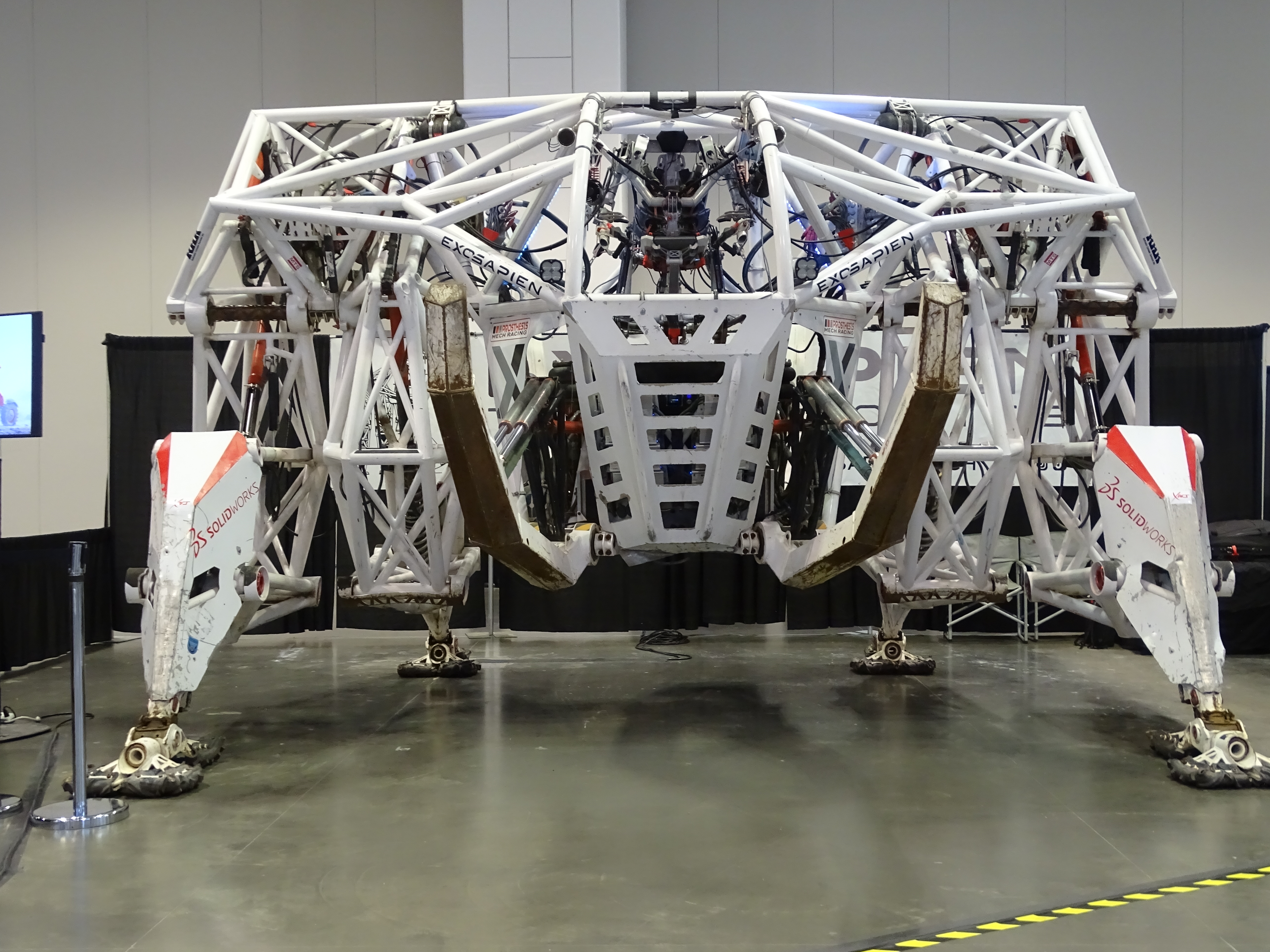

The last company promoted is surprising and imposing to say the least. It is called Exosapien and offers nothing more or less than the largest exoskeleton in the world (certified by the Guiness Book). The machine whose name is Prosthesis has outstanding characteristics. Judge rather: 4 meters high, 5.1 meters wide, a weight of 4 tons and a 200 horsepower electric motor. At the heart of the machine is a 96 volt 36 kWh lithium-ion battery pack capable of providing it with an autonomy of about 1 hour. Resembling a large spider with legs on pneumatic tires. Its designer, the Canadian Jonathan Tippet recalls that at the beginning the project had the ambition to “give humans the size and strength of giants”. In fact, the machine is capable of amplifying human strength by 50.

The size of Prosthesis is particularly impressive. (Photo Credit: JC)

Today, the mega-exoskeleton can be used in several use cases: mining, agriculture, forestry, human relief and in the context of disasters. It has two hooks on the front and back for lifting heavy loads. The piloting of the machine is carried out by a human and requires some learning. To design this machine, John Tippet turned rather quickly to Dassault Systèmes. “To develop our first prototype, we used Solidworks design tools and then they accompanied us in the evolution of the machine,” emphasizes the founder and inventor of Prosthesis. Materials, strength test, mechanics, assembly, the list is long of the elements supported by Solidworks. This partnership continues in the next adventure of Exosapiens, the VX1 EXO which looks like a quad bike. The first prototype should be released by the end of the year.

The next Exosapien system is a quad machine. (Photo Credit: Exosapien)