For Dassault Systèmes, cloud and automation are the future of design

On the occasion of its 3DExperience World 2023 Nashville event, Dassault Systmes insisted on the future of design with the development of industrial digital twins. To achieve this shift, the French publisher is counting on collaboration via the cloud and more and more automation.

Live from Nashville. Back in person for 3DExperience 2023 bringing together the Dassault Systèmes ecosystem, the last edition in physics took place in February 2020. The French publisher has chosen Nashville and the Music City Center to bring together customers and partners. A total of 10,000 people are expected over three days. Gian Paolo Bassi, executive vice-president of 3DExperience Works inaugurated this first day under the sign of design and eco-design. “Sustainable development and carbon impact issues are essential in the design of objects, machines and production lines,” he says. In this context, the PLM and CAD specialist will integrate an automatic environmental impact calculator into Solidworks depending on the materials chosen.

Cloud and virtual twin collaboration

Another point addressed in this inaugural session, the cloud. For Gian Paolo Bassi, “the future of design lies in collaboration”. In this context, he announces that from next July 1, each Solidworks workstation will include access to cloud services. This means that users of the platform will be able to “explore, test, improve” their initiatives through the services offered in the cloud. What are these services? there are several such as 3D Creator, 3D Sculptor, 3D SheetMetal Creator, etc. On the same date, the publisher also provides for the possibility for a Solidworks user to share his projects with anyone, without needing a license or installing a particular program. “He will have the ability to see the project to make comments, notifications, but not to edit it,” the manager explained to us.

Gian Paolo Bassi announced the possibility for Solidworks users to be able to share their project with other people. (Photo Credit: JC)

Still in the theme of the first day, “the future of design”, Bernard Charlès, President of Dassault Systèmes returned to the development of digital twins or what he calls “virtual twin”. He evoked the metaverse by distinguishing well “the risk of disillusionment” that this concept entails with the general public and the contributions for the manufacturers of the simulation. In its industrial version, “virtual twins are a reality”, but they require certain constraints. “They need to have a high-quality design”, he specifies because “they aim to reduce risks in real time”. In the midst of ChatGPT mania, the manager could not ignore the expectations in terms of AI by stressing that “generative AI will bring things into knowledge bases and the ability to replicate functional designs”. As proof of the enthusiasm on this topic, a full-fledged session on the OpenAI chatbot is planned during the event.

More automation within Solidworks

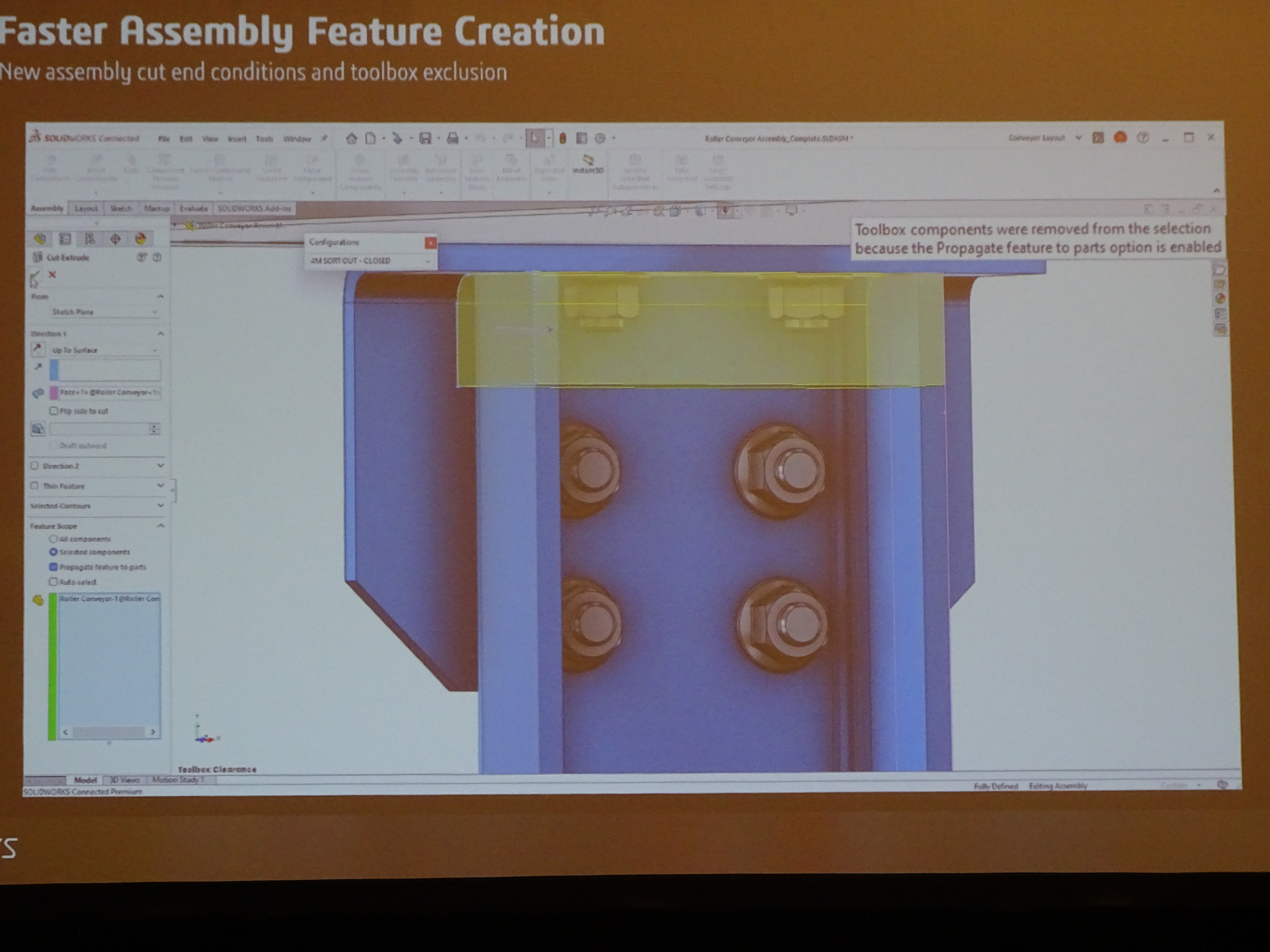

Apart from the cloud announcements, a session gave the main orientations of the novelties to expect in Solidworks and 3DExperience Works 2023. In the continuation of the previous presentations, the solutions will become more and more automated and collaborative. On the first point, Brian Zias, digital technical sales at Dassault Systèmes describes various product evolutions. For example, the design of complex structures will gain in performance by automating the combination of parts and their machining. The transparencies in the industrial design are better managed as are the assembly capabilities with the possibility of testing and excluding different models.

In Solidworks 2023, it is possible to manage the assembly capabilities (modification, replication and cutting). (Photo Credit: JC)

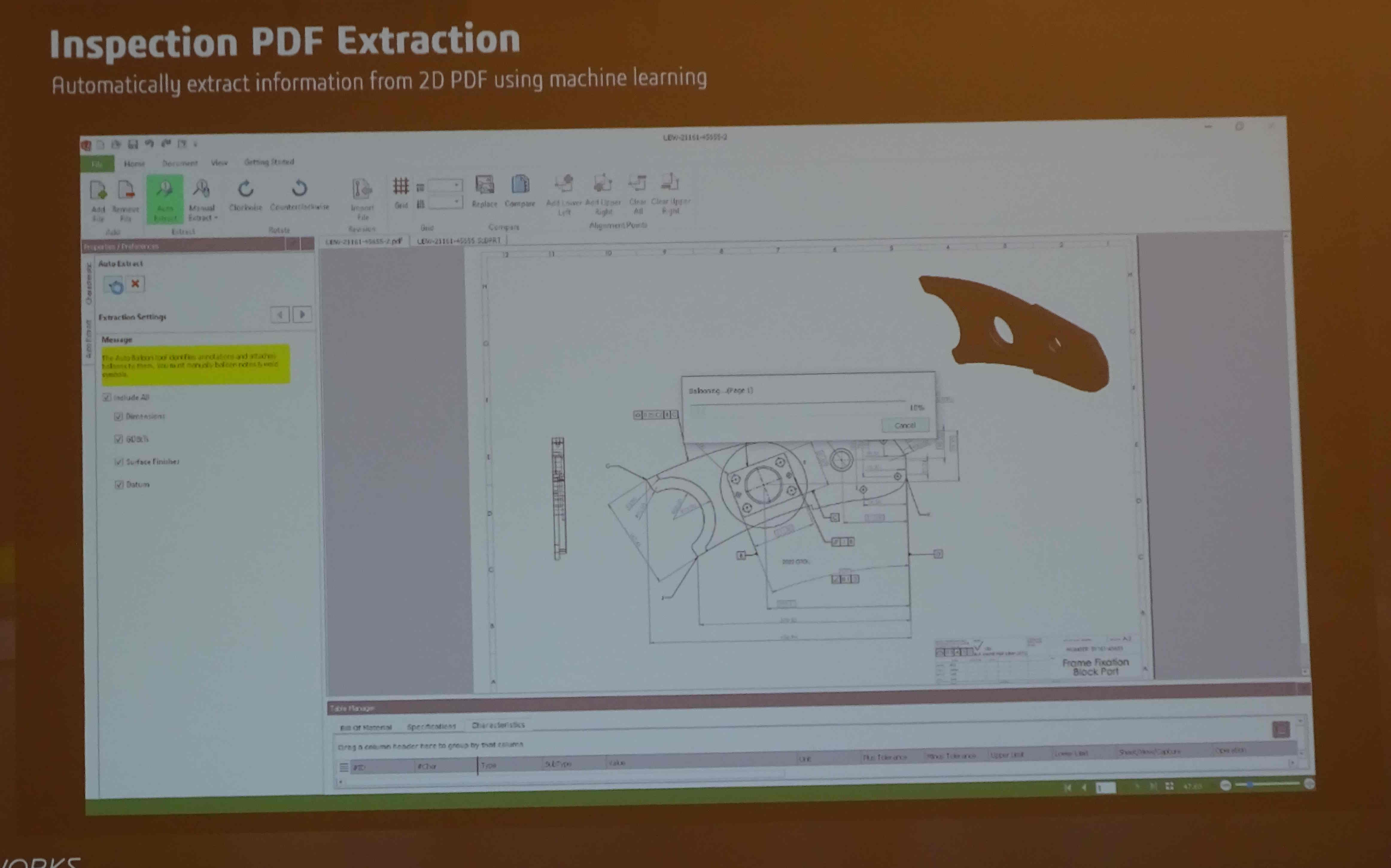

The other axis of development is the collaboration between the different design teams. For example, the PDM (product data management) solution will integrate custom notification templates. Automation is also in order with the contribution of machine learning in the automatic extraction of information from 2D documents in PDF. Users are able to model them, but also to check their quality. The documentation of the designed parts also becomes more dynamic with the possibility of changing elements in real time and letting its community know. Finally, the notion of real time is important and it is at the heart of the Solidworks Collaborative Designer service which gains in interaction on the design of a part.

Data extraction in 2D PDFs gains control and quality with machine learning. (Photo Credit: JC)